JUYOWA

Yayin juyawa, aikin aikin yana juyawa don samar da babban motsi na yanke.Lokacin da kayan aiki ke motsawa tare da madaidaiciyar axis na juyawa, an samar da saman cylindrical na ciki da na waje.Kayan aiki yana motsawa tare da layin da ba a sani ba yana tsaka da axis don samar da farfajiyar conical.A kan lathe profile ko CNC lathe, ana iya sarrafa kayan aikin don ciyarwa tare da lanƙwasa don samar da takamaiman yanayin juyin juya hali.Yin amfani da kayan aikin jujjuyawar kafa, ana kuma iya sarrafa saman jujjuya yayin ciyarwar ta gefe.Juyawa kuma na iya sarrafa saman zaren, jirage na ƙarewa da magudanar ruwa.Daidaiton juyowa gabaɗaya IT8-IT7 ne, kuma ƙarancin saman shine 6.3-1.6μm.Lokacin gamawa, zai iya kaiwa IT6-IT5, kuma rashin ƙarfi na iya kaiwa 0.4-0.1μm.Juyawa yana da mafi girman yawan aiki, tsarin yankan santsi da kayan aiki mafi sauƙi.

MILLING

Babban motsi na yanke shine juyawa kayan aiki.A lokacin niƙa a kwance, ƙirƙirar jirgin yana samuwa ta gefen gefen waje na mai yankan niƙa.A ƙarshen milling, jirgin yana samuwa ta gefen ƙarshen fuska na abin yankan niƙa.Ƙara saurin jujjuyawar mai yankan niƙa na iya samun babban saurin yankewa don haka mafi girman yawan aiki.Duk da haka, saboda yankewa da yankewa na hakoran hakoran hakoran hakoran hakora, an haifar da tasiri, kuma tsarin yankewa yana da haɗari ga rawar jiki, don haka yana iyakance haɓakar ingancin saman.Har ila yau, wannan tasiri yana kara lalacewa da lalacewa na kayan aiki, wanda sau da yawa yakan haifar da guntuwar abin da aka saka na carbide.A cikin lokaci na gaba lokacin da aka yanke aikin aiki, ana iya samun wani adadin sanyaya, don haka yanayin zafi ya fi kyau.Dangane da wannan ko gaban shugabanci na babban motsi gudun da workpiece feed shugabanci a lokacin milling, shi ne zuwa kashi ƙasa milling da sama milling.

1. Hawan niƙa

Ƙarfin ɓangaren kwance na ƙarfin milling iri ɗaya ne da jagorar ciyarwar aikin aikin.Gabaɗaya, akwai tazara tsakanin dunƙule feed na workpiece tebur da kafaffen goro.Saboda haka, da yankan karfi iya sauƙi sa workpiece da tebur ci gaba tare, haifar da ciyar kudi zama kwatsam.karuwa, yana haifar da wuka.A lokacin da ake niƙa kayan aiki masu wuya kamar simintin gyare-gyare ko ƙirƙira, haƙoran abin yankan niƙa na farko suna tuntuɓar fata mai wuyar aikin, wanda ke ƙara lalacewa na abin yankan niƙa.

2. Sama niƙa

Zai iya guje wa al'amuran motsi da ke faruwa yayin saukar niƙa.A lokacin yankan niƙa, kauri na yanke yana ƙaruwa a hankali daga sifili, don haka yankan gefen ya fara ɗanɗano lokacin matsi da zamewa a saman injin da aka yanke, yana haɓaka lalacewa na kayan aiki.A lokaci guda, yayin da ake yin niƙa, ƙarfin niƙa yana ɗaga kayan aikin, wanda ke da sauƙin haifar da girgiza, wanda shine rashin lahani na milling.

Daidaiton machining na niƙa na iya kaiwa ga IT8-IT7 gabaɗaya, kuma ƙarancin ƙasa shine 6.3-1.6μm.

Nika na yau da kullun na iya sarrafa filaye masu lebur kawai, kuma ƙirƙirar masu yankan niƙa kuma na iya aiwatar da ƙayyadaddun filaye masu lankwasa.Injin niƙa na CNC na iya amfani da software don sarrafa gatura da yawa waɗanda za a haɗa su bisa ga wata alaƙa ta tsarin CNC don niƙa rikitattun filaye masu lankwasa.A wannan lokacin, gabaɗaya ana amfani da abin yankan niƙa na ƙarshen ball.Injin niƙa na CNC suna da mahimmanci musamman don sarrafa kayan aikin aiki tare da hadaddun sifofi kamar ruwan wukake na injunan impeller, cores da cavities na molds.

SHIRYA

Lokacin shiryawa, motsi na linzamin linzamin na kayan aiki shine babban motsi na yanke.Sabili da haka, saurin shirin ba zai iya zama babba ba kuma yawan aiki yana da ƙasa.Planing ya fi karko fiye da niƙa, kuma daidaiton machining ɗin sa gabaɗaya zai iya kaiwa IT8-IT7, ƙarancin ƙasa shine Ra6.3-1.6μm, daidaitaccen shimfidar shimfidar wuri na iya isa 0.02/1000, kuma ƙarancin ƙasa shine 0.8-0.4μm.

Nika

Nika tafiyar da workpiece tare da nika dabaran ko wasu abrasive kayan aikin, da kuma babban motsi shi ne juyi na nika dabaran.The nika tsari na nika dabaran ne a zahiri hade sakamako na uku ayyuka na abrasive barbashi a kan surface na workpiece: yankan, engraving da zamiya.A lokacin niƙa, ƙwayoyin abrasive da kansu suna da hankali a hankali daga kaifi, wanda ke sa tasirin yanke ya fi muni kuma ƙarfin yanke yana ƙaruwa.Lokacin da ƙarfin yankan ya wuce ƙarfin m, zagaye da hatsi mara nauyi fallewa, fallasa sabon alkama na hasara, da samar da "kaifin kai" na nagarfin kai.Amma kwakwalwan kwamfuta da barbashi masu lalata suna iya toshe ƙafafun.Sabili da haka, bayan niƙa na ɗan lokaci, ya wajaba a yi ado da ƙafafun niƙa tare da kayan aikin juya lu'u-lu'u.

Lokacin niƙa, saboda akwai ruwan wukake da yawa, sarrafawa yana da kwanciyar hankali kuma yana da daidaito.Injin niƙa kayan aikin gamawa ne, daidaiton niƙa na iya isa IT6-IT4, kuma ƙarancin ƙasa Ra na iya kaiwa 1.25-0.01μm, ko ma 0.1-0.008μm.Wani fasalin nika shi ne cewa yana iya sarrafa kayan ƙarfe masu tauri.Sabili da haka, ana amfani dashi sau da yawa azaman matakin sarrafawa na ƙarshe.A lokacin niƙa, ana haifar da zafi mai yawa, kuma ana buƙatar isasshen ruwan yanka don sanyaya.Dangane da ayyuka daban-daban, ana iya raba niƙa zuwa niƙa na silinda, niƙa na ciki, niƙa lebur da sauransu.

HONKA da BAN GUDUMI

A kan na'ura mai hakowa, jujjuya rami tare da ramuka shine mafi yawan hanyoyin sarrafa ramuka.Daidaiton machining na hakowa yana da ƙasa, gabaɗaya kawai yana kaiwa IT10, kuma ƙarancin ƙasa gabaɗaya 12.5-6.3 μm.Bayan hakowa, ana amfani da reaming da reaming sau da yawa don kammalawa da ƙarewa.Ana amfani da rawar motsa jiki don reaming, kuma ana amfani da kayan aikin reaming don reaming.Daidaiton reaming gabaɗaya IT9-IT6 ne, kuma ƙarancin saman shine Ra1.6-0.4μm.Lokacin reaming da reaming, rawar soja bit da reamer gabaɗaya suna bin axis na ainihin ramin ƙasa, wanda ba zai iya inganta daidaiton ramin ba.M yana gyara matsayi na rami.Ana iya yin gundura akan na'ura mai ban sha'awa ko lathe.A lokacin da m a kan m inji, da m kayan aiki ne m guda a matsayin juya kayan aiki, sai dai cewa workpiece ba ya motsa da m kayan aiki juya.Madaidaicin machining mai ban sha'awa shine gabaɗaya IT9-IT7, kuma ƙarancin saman shine Ra6.3-0.8mm..

Hako Lathe mai ban sha'awa

HANYAR GYARAN HAKORI

Gear hakori hanyoyin machining surface za a iya raba kashi biyu: kafa hanyar da samar da hanya.Kayan aikin injin da aka yi amfani da shi don sarrafa saman hakori ta hanyar kafawa gabaɗaya injin niƙa ne na yau da kullun, kuma kayan aikin shine abin yankan niƙa, wanda ke buƙatar motsi masu sauƙi guda biyu: motsin juyawa na kayan aiki da motsi na madaidaiciya.Kayan aikin injin da aka saba amfani da shi don sarrafa saman hakori ta hanyar samar da hanya sun haɗa da injunan hobbing na kaya da injunan siffata kaya.

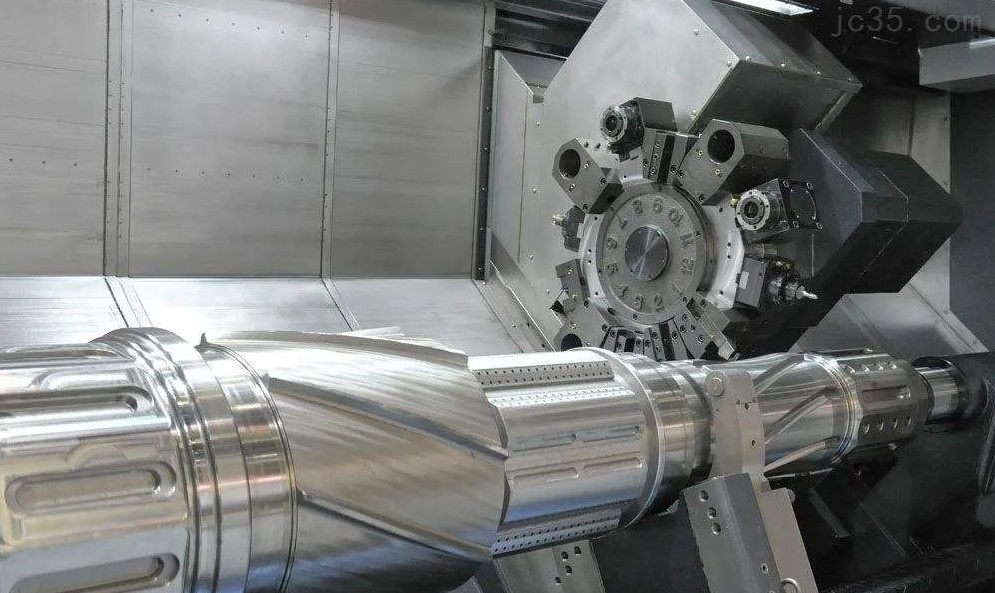

COMPLEX SURFAACE PROCESSING

Machining na sassa uku masu lankwasa galibi yana ɗaukar hanyoyin kwafi da niƙa da CNC ko hanyoyin sarrafawa na musamman (duba Sashe na 8).Kwafi niƙa dole ne ya sami samfuri a matsayin maigida.Yayin aiki, shugaban da ke bayyana kan ƙwallon yana koyaushe yana hulɗa da saman samfurin tare da wani matsi.Motsin da ke nuna kansa yana jujjuya shi zuwa inductance, kuma ƙararrawar sarrafawa yana sarrafa motsin gatari guda uku na injin niƙa, yana samar da yanayin mai yanke kan yana motsawa tare da lanƙwasa.Masu yankan niƙa galibi suna amfani da ƙwanƙwasa ƙarshen niƙa tare da radius iri ɗaya da kan mai bayanin martaba.Fitowar fasahar sarrafa lambobi yana ba da hanya mafi inganci don injinan saman.Lokacin yin aiki akan injin niƙa na CNC ko cibiyar mashin ɗin, ana sarrafa shi ta hanyar abin yankan niƙa na ƙarshen ƙwallon gwargwadon ma'aunin ƙimar daidaitawa.Amfanin yin amfani da cibiyar injina don aiwatar da filaye masu sarƙaƙƙiya shine cewa akwai mujallar kayan aiki akan cibiyar injinan, tana ɗauke da kayan aiki da dama.Don roughing da kuma gama na lankwasa saman, daban-daban kayan aikin za a iya amfani da daban-daban curvature radii na concave saman, da kuma dace kayan aikin za a iya zabar.A lokaci guda kuma, ana iya yin na'ura daban-daban na kayan taimako kamar ramuka, zaren, tsagi, da sauransu a cikin shigarwa ɗaya.Wannan yana ba da cikakken garantin daidaitaccen matsayi na kowane saman.

SARKI NA MUSAMMAN

Hanyar sarrafawa ta musamman tana nufin kalma gaba ɗaya don jerin hanyoyin sarrafawa waɗanda suka bambanta da hanyoyin yankan gargajiya da amfani da sinadarai, na zahiri (lantarki, sauti, haske, zafi, maganadisu) ko hanyoyin lantarki don aiwatar da kayan aikin aiki.Waɗannan hanyoyin injin ɗin sun haɗa da: injin sarrafa sinadarai (CHM), injin injin lantarki (ECM), mashin ɗin lantarki (ECMM), injin fitarwa na lantarki (EDM), injin sadarwar lantarki (RHM), injin ɗin ultrasonic (USM), injin injin laser (LBM), Ion Beam Machining (IBM), Electron Beam Machining (EBM), Plasma Machining (PAM), Electro-Hydraulic Machining (EHM), Abrasive Flow Machining (AFM), Abrasive Jet Machining (AJM), Liquid Jet Machining (HDM)) da kuma daban-daban hadawa aiki.

1. EDM

EDM shine a yi amfani da babban zafin jiki wanda ke haifar da fitar da walƙiya nan take tsakanin na'urar lantarki da na'urar lantarki don lalata saman kayan aikin don cimma mashin ɗin.Kayan aikin injin EDM gabaɗaya sun ƙunshi wadataccen wutar lantarki, injin ciyarwa ta atomatik, kayan aikin injin da tsarin tace ruwa mai aiki.An gyara kayan aikin akan teburin na'ura.Samar da wutar lantarki na bugun jini yana ba da kuzarin da ake buƙata don sarrafawa, kuma sandunansa biyu suna da alaƙa da na'urar lantarki da kayan aiki.Lokacin da na'urar lantarki da kayan aiki sun kusanci juna a cikin ruwa mai aiki da tsarin ciyarwa ke motsawa, ƙarfin lantarki tsakanin na'urorin lantarki yana rushe gibin don samar da fiɗa mai walƙiya da sakin zafi mai yawa.Bayan saman kayan aikin ya ɗauki zafi, ya kai wani matsanancin zafin jiki (sama da 10000 ° C), kuma kayan gida yana ɓalle saboda narkewa ko ma iskar gas, suna kafa ƙaramin rami.Tsarin tacewa mai aiki na ruwa mai aiki yana tilasta ruwa mai aiki mai tsabta ya wuce ta rata tsakanin injin lantarki da kayan aiki a wani matsa lamba, don cire samfuran lalata galvanic a cikin lokaci, kuma tace samfuran lalata galvanic daga ruwan aiki.Sakamakon fitowar da yawa, ana samar da adadin ramuka masu yawa a saman kayan aikin.Ana ci gaba da saukar da na'urar lantarki ta kayan aiki a ƙarƙashin tuƙi na injin ciyarwa, kuma siffar kwandon sa an “kwafi” zuwa aikin aikin (ko da yake kayan lantarki na kayan aiki kuma za a lalatar da shi, saurin sa ya ragu da na kayan aikin).Kayan aikin injin EDM don sarrafa kayan aiki masu dacewa tare da kayan aikin lantarki na musamman

① Gudanar da wuya, gaggautsa, tauri, taushi da high narkewa batu conductive kayan;

②Tsarin kayan aikin semiconductor da kayan da ba sa aiki;

③ Tsara nau'ikan ramuka daban-daban, ramukan lanƙwasa da ƙananan ramuka;

④ Tsara sassa daban-daban masu lankwasa cavities, kamar su ƙirƙira mutuwa, mutuwar-simintin mutuwa, da mutuwar filastik;

⑤An yi amfani da shi don yankan, yankan, ƙarfafa farfajiya, zane-zane, bugu da alamun suna, da sauransu.

Waya EDM Machine Tool don Machining 2D Profile Siffar Workpieces tare da Waya Electrodes

2. Electrolytic machining

Electrolytic machining wata hanya ce ta samar da workpieces ta amfani da ka'idar electrochemical na anodic rushe karafa a cikin electrolytes.A workpiece an haɗa zuwa tabbatacce iyakacin duniya na wutar lantarki DC, da kayan aiki da aka haɗa zuwa korau iyakacin duniya, da kuma wani karamin rata (0.1mm ~ 0.8mm) da aka kiyaye tsakanin biyu sanduna.Electrolyte tare da wani matsa lamba (0.5MPa~2.5MPa) yana gudana ta rata tsakanin sandunan biyu a babban gudun 15m/s~60m/s.Lokacin da kayan aikin cathode ke ci gaba da ciyar da kayan aiki, a saman kayan aikin da ke fuskantar cathode, kayan ƙarfe yana ci gaba da narkar da su gwargwadon siffar bayanan cathode, kuma samfuran electrolysis ana ɗaukar su ta hanyar lantarki mai sauri. don haka siffar bayanin martabar kayan aiki daidai yake "kofe" akan kayan aikin.

①A aiki ƙarfin lantarki ne kananan da kuma aiki halin yanzu ne babba;

② Gudanar da bayanin martaba mai rikitarwa ko rami a lokaci guda tare da motsi mai sauƙi;

③ Yana iya sarrafa kayan aiki masu wahala;

④ Babban yawan aiki, game da 5 zuwa 10 sau na EDM;

⑤ Babu wani ƙarfin yankan injin ko yanke zafi yayin aiki, wanda ya dace da sarrafa nakasassu cikin sauƙi ko sassa na bakin ciki;

⑥Matsakaicin haƙurin machining na iya kaiwa kusan ± 0.1mm;

⑦ Akwai kayan aikin taimako da yawa, suna rufe babban yanki da tsada mai tsada;

⑧Electrolyte ba wai kawai lalata kayan aikin injin bane, amma kuma cikin sauki yana gurbata muhalli.Ana amfani da kayan aikin lantarki da yawa don sarrafa ramuka, ramuka, bayanan martaba masu rikitarwa, ƙananan ramuka masu zurfin diamita, harbi, ɓarna, da zane-zane.

3. sarrafa Laser

The Laser aiki na workpiece aka kammala ta Laser sarrafa inji.Na'urorin sarrafa Laser yawanci sun ƙunshi na'urori masu amfani da wutar lantarki, tsarin gani da tsarin injina.Lasers (wanda aka fi amfani da Laser mai ƙarfi-jihar da Laser gas) suna canza makamashin lantarki zuwa makamashin haske don samar da katako na Laser da ake buƙata, waɗanda ke mai da hankali ta hanyar tsarin gani sannan kuma a haskaka a kan kayan aikin don sarrafawa.An gyara kayan aikin akan madaidaicin madaidaicin ma'auni guda uku, wanda tsarin kula da lambobi ke sarrafawa da sarrafa shi don kammala motsin ciyarwar da ake buƙata don sarrafawa.

①Ba a buƙatar kayan aikin injin;

② Ƙarfin ƙarfin wutar lantarki na laser yana da girma sosai, kuma yana iya sarrafa kusan kowane ƙarfe da kayan da ba na ƙarfe ba waɗanda ke da wuyar sarrafawa;

③ Laser aiki ba lamba aiki, kuma workpiece ba nakasassu da karfi;

④ Gudun hakowa da yankan Laser yana da girma sosai, kayan da ke kewaye da sashin sarrafawa ba su da wahala ta hanyar yankan zafi, kuma lalatawar thermal na workpiece yana da ƙanƙanta.

⑤ The tsaga na Laser yankan ne kunkuntar, da yankan gefen ingancin ne mai kyau.Laser sarrafa da aka yadu amfani a cikin lu'u-lu'u zane zanen mutu, agogon gem bearings, porous konkoma karãtunsa fãtun na divergent iska sanyaya punches, kananan rami sarrafa injin man allura nozzles, Aero-injin, da dai sauransu, kazalika da yankan daban-daban karfe kayan. da kayan da ba na karfe ba..

4. Ultrasonic aiki

Ultrasonic machining wata hanya ce a cikin abin da ƙarshen fuskar kayan aiki yana girgiza tare da mita ultrasonic (16KHz ~ 25KHz) yana tasiri da dakatarwar abrasive a cikin ruwa mai aiki, da barbashi mai lalacewa da tasiri da goge saman kayan aikin don gane machining na workpiece. .Na'urar janareta ta ultrasonic tana jujjuya mitar wutar lantarki AC makamashin lantarki zuwa mitar wutar lantarki ta ultrasonic tare da takamaiman fitarwar wutar lantarki, kuma yana jujjuya mitar wutar lantarki ta ultrasonic zuwa girgizar injin ultrasonic ta hanyar transducer.0.01mm yana ƙara girma zuwa 0.01 ~ 0.15mm, yana motsa kayan aiki don girgiza.Ƙarshen fuskar kayan aiki yana tasiri ga ɓangarorin da aka dakatar da su a cikin ruwa mai aiki a cikin rawar jiki, don haka ya ci gaba da bugawa da goge saman da za a yi amfani da shi a babban gudun, kuma yana murƙushe kayan da ke cikin wurin sarrafawa zuwa ɓangarorin da ke da kyau sosai da kuma buga. ta kasa.Ko da yake akwai ɗan ƙaramin abu a cikin kowane bugu, har yanzu akwai takamaiman saurin sarrafawa saboda yawan busa.Saboda yawowar ruwan aiki, abubuwan da aka buga ana ɗaukar su cikin lokaci.Yayin da ake ci gaba da shigar da kayan aikin, ana “kwafe siffarsa” akan kayan aikin.

Lokacin sarrafa kayan da ke da wuyar yankewa, ana haɗa vibration na ultrasonic sau da yawa tare da wasu hanyoyin sarrafawa don sarrafa abubuwa masu haɗaka, kamar juyawa ultrasonic, ultrasonic nika, ultrasonic electrolytic machining, da ultrasonic waya yankan.Waɗannan hanyoyin sarrafa abubuwa masu haɗaka sun haɗu da hanyoyin sarrafawa biyu ko ma fiye da haka, waɗanda zasu iya haɓaka ƙarfin juna, kuma suna haɓaka ingantaccen aiki, daidaiton aiki da ingancin saman kayan aikin.

ZABEN HANYAR SARKI

Zaɓin hanyar sarrafawa ya fi la'akari da siffar farfajiyar ɓangaren, daidaiton girman girman da buƙatun daidaiton matsayi, buƙatun ƙaƙƙarfan yanayi, da kayan aikin injin da ke akwai, kayan aikin da sauran albarkatu, tsari na samarwa, yawan aiki da bincike na tattalin arziki da fasaha. da sauran dalilai.

Hanyar Injiniya don Filaye Na Musamman

1. Hanyar machining na waje

- 1. Juyawa mai kauri → kammalawa → gamawa:

Mafi yawan amfani, gamsarwa IT≥IT7, ▽≥0.8 za a iya sarrafa da'irar waje

- 2. Juyawa mai kauri → juyi juzu'i na ƙarewa → niƙa mai laushi → niƙa mai kyau:

Ana amfani dashi don ƙarfe na ƙarfe tare da buƙatun quenching IT≥IT6, ▽≥0.16.

- 3. Juyawa mai kaushi → Juyawa juyi → gamawa juyi → juyar da lu'u-lu'u:

Don karafa marasa ƙarfe, saman waje waɗanda ba su dace da niƙa ba.

- 4. Rough Juyawa → Semi-Finishing → M nika → lafiyayye nika → nika, super-finishing, bel nika, madubi nika, ko polishing domin kara gamawa a kan tushen 2.

Manufar ita ce a rage taurin kai da inganta daidaiton girma, siffa da daidaiton matsayi.

2. Hanyar sarrafa ramin

- 1. Drill → m ja → kyau ja:

Ana amfani da shi don sarrafa rami na ciki, rami maɓalli guda ɗaya da ramin spline don yawan samar da sassan hannun rigar diski, tare da ingantaccen aiki mai ƙarfi da ingantaccen samarwa.

- 2. Drill → Fadada → Ream → Sake Hannu:

Ana amfani da shi don sarrafa ƙananan ramuka da matsakaitan ramuka, daidaita daidaiton matsayi kafin yin reaming, da reaming don tabbatar da girman girman, daidaiton siffar da tarkace.

- 3. Drilling or m boring → Semi-finishing boring → lafiyayye mai ban sha'awa → iyo mai ban sha'awa ko lu'u-lu'u mai ban sha'awa

aikace-aikace:

1) sarrafa pore akwatin a cikin guda-yanki kananan tsari samar.

2) Ramin aiki tare da babban matsayi daidai bukatun.

3) Ramin da ke da babban diamita ya fi ф80mm, kuma an riga an sami ramukan da aka jefa ko ramukan ƙirƙira akan babur.

4) Non-ferrous karafa da lu'u-lu'u m don tabbatar da girman, siffar da matsayi daidaito da surface roughness bukatun.

- 4. /Drilling (rough boring) m nika → Semi-finishing → lafiya nika → nika ko nika

Aikace-aikace: machining na taurare sassa ko rami machining tare da high ainihin bukatun.

kwatanta:

1) Daidaiton mashin ɗin ƙarshe na rami ya dogara da matakin mai aiki.

2) Ana amfani da hanyoyin sarrafawa na musamman don sarrafa ƙarin ƙananan ramuka.

3.hanyar sarrafa jirgin sama

- 1. Milling m milling → Semi-ƙare → Tsakanin → High-Saurin Milging

Yawanci ana amfani da shi wajen sarrafa jirgin sama, dangane da buƙatun fasaha na madaidaici da ƙaƙƙarfan yanayin saman da aka sarrafa, ana iya tsara tsarin da sassauƙa.

- .

Ana amfani dashi ko'ina kuma yana da ƙarancin aiki.Ana amfani da shi sau da yawa wajen sarrafa kunkuntar saman da tsayi.Tsarin tsari na ƙarshe kuma ya dogara da buƙatun fasaha na farfajiyar injin.

- 3. Milling (planing) → Semi-finishing (planing) → m nika → lafiya nika → nika, daidaici nika, bel nika, polishing

Wurin da aka yi amfani da shi yana ƙarewa, kuma tsarin ƙarshe ya dogara da buƙatun fasaha na kayan aikin da aka yi.

- 4. ja → kyau ja

Samar da girma mai girma yana da tsattsauran filaye ko matakai.

- 5. Juyawa →Kammala Juyawa →Kammala Juyawa → Juyawar Lu'u-lu'u

Flat machining na ƙarfe ba na ƙarfe ba.

Lokacin aikawa: Agusta-20-2022