Dangane da tsarin shirye-shiryen na samfuran kayan aikin injin, kayan aikin injin sun kasu kashi 11: lathes, injunan hakowa, injuna masu ban sha'awa, injin niƙa, injin sarrafa kaya, injin zare, injin niƙa, injin injin planer, injin buɗaɗɗen ruwa, injunan yanka da sauran su. kayan aikin injin.A cikin kowane nau'in kayan aikin injin, an raba shi zuwa ƙungiyoyi da yawa bisa ga kewayon tsari, nau'in shimfidawa da aikin tsarin, kuma kowane rukuni ya kasu kashi da yawa.A yau, editan zai yi magana da ku game da labarun tarihi na lathes, injuna masu ban sha'awa da injin niƙa.

1. Latsa

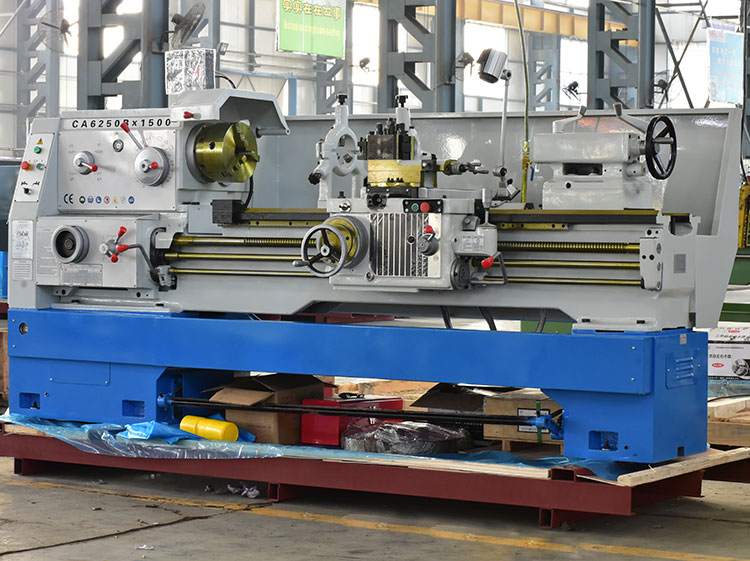

Lathe kayan aiki ne na inji wanda galibi yana amfani da kayan aikin juyawa don jujjuya kayan aiki.A kan lathe, drills, reamers, reamers, famfo, mutu da kuma kayan aikin ƙwanƙwasa suma ana iya amfani da su don aiki daidai.An fi amfani da lathes don machining shafts, fayafai, hannayen riga da sauran kayan aiki tare da filaye masu juyawa, kuma sune nau'in kayan aikin injin da aka fi amfani dashi a masana'antar injina da shagunan gyarawa.

1. “Lathe baka” na d ¯ a da sandunan baka.Tun a zamanin d Misira, mutane sun ƙirƙiro fasahar juya itace da kayan aiki yayin da suke jujjuya shi a kusa da kusurwoyin tsakiyarta.Da farko, mutane sun yi amfani da katako guda biyu a matsayin abin tallafi don kafa itacen da za a juya, suna amfani da ƙarfin roba na rassan don mirgina igiyar a kan itacen, suna jan igiyar da hannu ko ƙafa don juya itacen, kuma su riƙe wuka don yin amfani da ita. yankan.

Wannan tsohuwar hanya a hankali ta samo asali kuma ta haɓaka zuwa juzu'i biyu ko uku na igiyar a kan ɗigon, igiyar tana goyan bayan sandar roba da aka lanƙwasa ta zama siffa ta baka, ana tura baka ana ja da baya da baya don juya abin da aka sarrafa don juyawa, wanda shine "lathe baka".

2. Tsakanin crankshaft da tuƙin ƙafar ƙafa "lathe fedal".A Tsakiyar Tsakiyar Zamani, wani ya ƙirƙira “lathe pedal” wanda ya yi amfani da feda don jujjuya ƙugiya da tuƙi, sannan ya tuƙa shi zuwa babban ramin don juya shi.A tsakiyar karni na 16, wani mai zanen Faransa mai suna Besson ya ƙera lathe don juya screws tare da sandar dunƙule don yin zamewar kayan aikin.Abin takaici, wannan lathe ɗin bai shahara ba.

3. A cikin karni na sha takwas, an haifi akwatunan gado da chucks.A cikin karni na 18, wani ya tsara lathe wanda ke amfani da fedar ƙafa da sandar haɗi don juya crankshaft, wanda zai iya adana ƙarfin motsin motsin motsi a kan jirgin sama, kuma ya haɓaka daga jujjuya kayan aiki kai tsaye zuwa wani katako mai juyawa, wanda shine The chuck don rike da workpiece.

4. A cikin 1797, Bature Maudsley ya ƙirƙira kayan aiki na zamani bayan lathe, wanda ke da madaidaicin dunƙule gubar da kayan maye.

An haifi Maudsley a shekara ta 1771, kuma yana da shekaru 18, shi ne na hannun daman mai kirkiro Brammer.An ce Brammer ya kasance manomi ne, kuma tun yana dan shekara 16, wani hatsari ya haifar da nakasu a idon sawunsa na dama, don haka sai ya koma sana’ar katako, wanda ba shi da hannu sosai.Kirkirar farko da ya yi ita ce bandaki a shekara ta 1778. Maudsley ya fara taimakawa Brahmer ya kera injinan ruwa da sauran injuna har sai da ya bar Brahmer yana da shekaru 26, saboda rashin kunya Brahmer ya ki amincewa da shawarar Moritz na neman karin albashi sama da shilling 30 a mako.

A cikin wannan shekarar da Maudsley ya bar Brammer, ya gina lathe ɗin zaren sa na farko, lathe-metal lathe tare da mariƙin kayan aiki da tarkacen wutsiya mai iya tafiya tare da layin dogo guda biyu.Fuskar jagorar dogo mai jagora mai siffar triangular ne, kuma lokacin da igiya ta juya, ana kora dunƙule gubar don matsar da mariƙin kayan aiki a gefe.Wannan shi ne babban tsarin lathes na zamani, wanda da shi za a iya juya madaidaicin screws na kowane farar.

Shekaru uku bayan haka, Maudsley ya gina cikakken lathe a cikin nasa bita, tare da kayan aiki masu musanyawa waɗanda suka canza ƙimar ciyarwa da ƙirar zaren da ake sarrafa su.A shekara ta 1817, wani Baturen Ingila, Roberts, ya ɗauki tsarin juzu'i mai hawa huɗu da na baya don canza saurin igiya.Ba da daɗewa ba, an ƙaddamar da manyan lathes, waɗanda suka ba da gudummawa ga ƙirƙirar injin tururi da sauran injina.

5. Haihuwar lathes na musamman daban-daban Don haɓaka matakin injina da sarrafa kansa, Fitch a Amurka ya ƙirƙira lathe turret a 1845;a cikin 1848, wani lathe wheel ya bayyana a Amurka;a shekara ta 1873, Spencer a Amurka ya yi igiya guda ɗaya ta atomatik, kuma ba da daɗewa ba ya yi lathes ta atomatik mai axis uku;a farkon karni na 20th akwai lathes tare da kayan watsa kayan aiki da ke motsa jiki daban-daban.Sakamakon ƙera ƙarfe na kayan aiki mai sauri da kuma amfani da injinan lantarki, an ci gaba da inganta lathes kuma a ƙarshe sun kai matakin zamani na babban sauri da daidaito.

Bayan yakin duniya na farko, saboda bukatu na makamai, motoci da sauran masana'antu na injuna, manyan lathes na atomatik iri-iri da na musamman sun haɓaka cikin sauri.Domin inganta yawan aiki na kananan batches na workpieces, a cikin marigayi 1940s, an inganta lathes tare da na'ura mai ba da hanya tsakanin hanyoyin sadarwa, kuma a lokaci guda, Multi-kayan lathes an kuma ɓullo da.A tsakiyar shekarun 1950, an ƙera lathes masu sarrafa shirye-shirye tare da katunan naushi, farantin latch da dial.An fara amfani da fasahar CNC a cikin lathes a cikin 1960s kuma ta haɓaka cikin sauri bayan 1970s.

6. Lathes sun kasu kashi daban-daban bisa ga amfani da aikinsu.

Lathe na yau da kullun yana da abubuwa da yawa na sarrafawa, kuma daidaitawar kewayon saurin sandal da abinci yana da girma, kuma yana iya aiwatar da saman ciki da na waje, fuskokin ƙarewa da zaren ciki da na waje na workpiece.Wannan nau'in lathe galibi ana sarrafa shi da hannu ta ma'aikata, tare da ƙarancin samarwa, kuma ya dace da yanki ɗaya, samar da ƙaramin tsari da kuma wuraren gyarawa.

Turret lathes da Rotary lathes suna da kayan aiki na turret ko sauran kayan aikin rotary wanda zai iya ɗaukar kayan aiki da yawa, kuma ma'aikata na iya amfani da kayan aikin daban-daban don kammala matakai daban-daban a cikin ɗaki ɗaya na workpiece, wanda ya dace da samarwa da yawa.

Lathe ta atomatik na iya kammala aikin aiki da yawa na ƙanana da matsakaita-matsakaici bisa ga wani shirin, na iya ɗauka ta atomatik da sauke kayan aiki, da aiwatar da tsari iri ɗaya akai-akai, wanda ya dace da samarwa da yawa.

Multi-kayan aiki Semi-atomatik lathes an raba zuwa guda-axis, Multi-axis, a kwance da kuma a tsaye.Siffar nau'in kwancen axis guda ɗaya yana kama da na lathe na yau da kullun, amma saitin kayan aiki guda biyu ana sanya su a gaba da baya ko sama da ƙasa na babban shaft, bi da bi, kuma ana amfani da su don sarrafa fayafai; zobe da shaft workpieces, da yawan aiki ne 3 zuwa 5 sau fiye da na talakawa lathes.

Lathe mai bayanin martaba na iya kammala zagayowar mashin ɗin ta atomatik ta yin kwaikwayon siffar da girman samfuri ko samfurin.Ya dace da ƙaramin tsari da samar da kayan aiki tare da sifofi masu rikitarwa, kuma yawan aiki shine sau 10 zuwa 15 sama da na lathes na yau da kullun.Akwai mariƙin kayan aiki da yawa, Multi-axis, nau'in chuck, nau'in tsaye da sauran nau'ikan.

Sanda na lathe a tsaye yana tsaye zuwa jirgin sama a kwance, aikin aikin yana manne akan tebur na jujjuyawar kwance, kuma kayan aikin yana motsawa akan katako ko ginshiƙi.Ya dace da sarrafa manyan kayan aiki masu nauyi waɗanda ke da wahalar shigar akan lathes na yau da kullun.Gabaɗaya, sun kasu kashi biyu: ginshiƙi ɗaya da ginshiƙi biyu.

Duk da yake shebur hakori lathe yana juya, da kayan aiki mariƙin lokaci-lokaci reciprocates a cikin radial shugabanci, wanda ake amfani da forming hakori saman na forklift milling cutters, hob cutters, da dai sauransu Yawancin lokaci tare da taimako nika abin da aka makala, karamin nika dabaran kore ta daban. injin lantarki yana sauƙaƙa saman hakori.

Lathes na musamman sune lathes da ake amfani da su don injin takamaiman saman wasu nau'ikan kayan aiki, kamar su lathes crankshaft, camshaft lathes, lathes na dabaran, lathes axle, nadi lathes, da ingot lathes.

An fi amfani da lathe ɗin da aka haɗe don sarrafawa, amma bayan ƙara wasu sassa na musamman da na'urorin haɗi, yana iya yin gundura, niƙa, hakowa, saka, niƙa da sauran sarrafawa.Yana da halaye na "na'ura ɗaya tare da ayyuka masu yawa" kuma ya dace da motocin injiniya, jiragen ruwa ko aikin gyaran wayar hannu a wurin gyarawa.

Duk da cewa sana’ar bita tana da koma baya, amma ta horar da kuma samar da masu sana’a da dama.Duk da cewa ba ƙwararru ba ne wajen kera inji, amma za su iya kera kowane irin kayan aikin hannu, kamar wuƙaƙe, zato, allura, ƙwanƙwasa, mazugi, injin niƙa, ramuka, hannun riga, gears, firam ɗin gado, da dai sauransu, a haƙiƙanin haka, injinan harhada su ne. daga wadannan sassa.

1. Mawallafin farko na na'ura mai ban sha'awa - Da Vinci na'ura mai ban sha'awa da ake kira "Uwar Machinery".Da yake magana game da inji mai ban sha'awa, dole ne mu fara magana game da Leonardo da Vinci.Wannan adadi na almara na iya zama wanda ya ƙera na'urori na farko masu ban sha'awa don aikin ƙarfe.Na'ura mai ban sha'awa da ya zana ana amfani da ita ta na'ura mai aiki da karfin ruwa ko ƙafar ƙafa, kayan aiki mai ban sha'awa yana jujjuya kusa da kayan aikin, kuma kayan aikin yana daidaitawa akan teburin wayar hannu da crane ke tukawa.A cikin 1540, wani mai zane ya zana hoton "Pyrotechnics" tare da zane iri ɗaya na na'ura mai ban sha'awa, wanda aka yi amfani da shi don kammala simintin gyare-gyare a lokacin.

2. Na'ura mai ban sha'awa na farko da aka haifa don sarrafa ganga na cannon (Wilkinson, 1775).A karni na 17, saboda bukatu na soji, ana samun saurin bunkasuwar kera makaman, kuma yadda ake kera ganga ta zama babbar matsala da mutane ke bukatar a warware cikin gaggawa.

Wilkinson ya ƙirƙira na'ura mai ban sha'awa ta farko a duniya a cikin 1775. A gaskiya ma, na'ura mai ban sha'awa ta Wilkinson, ita ce, daidai, injin hakowa mai iya yin daidaitattun machining cannons, mashaya mai ban sha'awa na silindical mai raɗaɗi wanda aka saka a kan bearings a ƙarshen duka.

An haife shi a Amurka a 1728, Wilkinson ya koma Staffordshire yana da shekaru 20 don gina tanderun ƙarfe na farko na Bilston.Saboda wannan dalili, ana kiran Wilkinson "Master Blacksmith na Staffordshire".A shekara ta 1775, yana da shekaru 47, Wilkinson ya yi aiki tuƙuru a masana'antar mahaifinsa don ƙirƙirar wannan sabuwar na'ura da za ta iya haƙa ganga na gwangwani da ƙarancin gaske.Abin sha'awa shine, bayan da Wilkinson ya mutu a shekara ta 1808, an binne shi a cikin akwatin gawa na simintin ƙarfe na ƙirarsa.

3. Na'ura mai ban sha'awa ta ba da gudummawa mai mahimmanci ga injin tururi na Watt.Tashin farko na juyin juya halin masana'antu ba zai yiwu ba in ba tare da injin tururi ba.Don haɓakawa da aikace-aikacen injin tururi kanta, baya ga damar zamantakewar da ake buƙata, ba za a iya yin watsi da wasu buƙatun fasaha ba, saboda kera sassan injin tururi ba shi da sauƙi kamar yankan itace ta wurin kafinta.Wajibi ne don yin wasu nau'ikan nau'ikan ƙarfe na musamman, kuma buƙatun daidaiton aiki suna da girma, waɗanda ba za a iya cimma su ba tare da kayan aikin fasaha masu dacewa.Misali, a cikin kera silinda da fistan injin tururi, ana iya yanke daidaiton diamita na waje da ake buƙata a cikin tsarin masana'anta na fistan yayin auna girman, amma don saduwa da daidaiton buƙatun ciki. diamita na Silinda, ba shi da sauƙi don amfani da hanyoyin sarrafawa na gaba ɗaya..

Smithton shine mafi kyawun makanike na karni na sha takwas.Smithton ya ƙirƙira kusan guda 43 na ruwa da kayan injin niƙa.Lokacin da ya zo ga yin injin tururi, abu mafi wahala ga Smithon shine sarrafa silinda.Yana da wuya a iya injin babban da'irar ciki ta Silinda zuwa da'irar.Don wannan karshen, Smithton ya yi na'ura na musamman don yankan da'irar ciki na Silinda a Cullen Iron Works.Wannan nau’in na’ura mai ban sha’awa, wadda ake amfani da keken ruwa, tana dauke da kayan aiki a gaban doguwar kusurwar sa, kuma ana iya jujjuya na’urar a cikin silinda don sarrafa da’irar ta ciki.Tun lokacin da aka shigar da kayan aiki a gaban ƙarshen dogon zangon, za a sami matsaloli irin su karkatar da shaft, don haka yana da matukar wahala a yi amfani da silinda madauwari da gaske.Don wannan karshen, Smithton ya canza matsayi na Silinda sau da yawa don mashina.

Na'ura mai ban sha'awa da Wilkinson ya ƙirƙira a shekara ta 1774 ta taka rawa sosai a cikin wannan matsala.Irin wannan na'ura mai ban sha'awa yana amfani da motar ruwa don juya silinda kayan aiki kuma ya tura shi zuwa ga kayan aiki da aka gyara a tsakiya.Saboda motsin dangi tsakanin kayan aiki da kayan aiki, kayan yana gundura a cikin rami na cylindrical tare da madaidaicin madaidaici.A lokacin, an yi amfani da na'ura mai ban sha'awa don yin silinda mai diamita na 72 inci a cikin kauri na tsabar kudi sittin.Idan aka auna da fasahar zamani, wannan babban kuskure ne, amma a karkashin yanayin da ake ciki a lokacin, ba a samu saukin kai wannan matakin ba.

Duk da haka, ƙirƙirar da Wilkinson ya ƙirƙira ba ta da haƙƙin mallaka ba, kuma mutane sun kwafi kuma suka shigar da shi.A cikin 1802, Watt kuma ya rubuta game da ƙirƙirar Wilkinson, wanda ya kwafi a Soho ironworks.Daga baya, lokacin da Watt ya yi silinda da pistons na injin tururi, ya kuma yi amfani da wannan na'ura mai ban mamaki na Wilkinson.Ya bayyana cewa don piston, yana yiwuwa a auna girman yayin yanke shi, amma ba haka ba ne mai sauƙi ga Silinda, kuma dole ne a yi amfani da na'ura mai ban sha'awa.A lokacin, Watt ya yi amfani da dabaran ruwa don jujjuya silinda na karfe, don haka an tura kayan aikin da aka kafa a gaba don yanke cikin silinda.Sakamakon haka, kuskuren silinda mai diamita na inci 75 bai kai kaurin tsabar kuɗi ba.Yana da ci gaba sosai.

4. Haihuwar na'ura mai ban sha'awa mai ɗaukar tebur (Hutton, 1885) A cikin shekaru masu zuwa, an sami gyare-gyare da yawa ga na'ura mai ban sha'awa na Wilkinson.A shekara ta 1885, Hutton a Birtaniya ya kera na'urar daga tebur mai ban sha'awa, wanda ya zama samfurin na'ura na zamani.

3. Injin niƙa

A karni na 19, turawan ingila suka kirkiro na'ura mai ban sha'awa da na'ura don bukatuwar juyin juya halin masana'antu kamar injin tururi, yayin da Amurkawa suka mayar da hankali kan kera na'urar niƙa don kera makamai masu yawa.Injin niƙa inji ne mai yankan niƙa na sifofi daban-daban, waɗanda za su iya yanke kayan aiki tare da sifofi na musamman, kamar tsagi mai ƙarfi, sifofin kaya, da sauransu.

Tun a shekara ta 1664, masanin kimiyar Biritaniya Hook ya ƙirƙiro na'ura don yankan ta hanyar dogaro da masu yankan madauwari.Ana iya ɗaukar wannan a matsayin na'urar niƙa ta asali, amma a lokacin al'umma ba su amsa da ƙwazo ba.A cikin 1840s, Pratt ya tsara abin da ake kira Lincoln milling machine.Tabbas, wanda ya tabbatar da matsayin injin niƙa a masana'antar injin shine Whitney na Amurka.

1. Na'urar niƙa ta farko ta farko (Whitney, 1818) A cikin 1818, Whitney ta yi na'urar milling ta farko a duniya, amma ikon mallakar injin niƙa shine British Bodmer (tare da na'urar ciyar da kayan aiki).Wanda ya kirkiro gantry planer) "an samu" a shekara ta 1839. Saboda tsadar injunan niƙa, babu mutane da yawa da suke sha'awar a lokacin.

2. Na'urar niƙa ta farko ta duniya (Brown, 1862) Bayan ɗan lokaci shiru, injin niƙa ya sake yin aiki a Amurka.Sabanin haka, Whitney da Pratt ne kawai za a iya cewa sun kafa harsashin ƙirƙira da aikace-aikacen injin niƙa, kuma ya kamata a ce an ba da lamuni na ƙirƙira na'urar niƙa da gaske da za a iya amfani da ita ga ayyuka daban-daban a masana'anta ga injiniyan Ba'amurke. Joseph Brown.

A shekara ta 1862, Brown a Amurka ya samar da injin niƙa na farko a duniya, wanda ya kasance sabon zamani na samar da faya-fayan fayafai da kuma ingantattun injinan niƙa.Tebur na injin niƙa na duniya na iya juyawa wani kusurwa a cikin madaidaiciyar hanya, kuma yana da kayan haɗi kamar shugaban niƙa na ƙarshe.“Na’urar niƙa ta duniya” ta sami babban nasara a lokacin da aka baje kolin ta a bikin baje kolin na Paris a shekara ta 1867. A lokaci guda kuma, Brown ya ƙera abin yankan niƙa da ba zai lalace ba bayan niƙa, sannan ya kera injin niƙa don niƙa niƙa. abin yanka, yana kawo injin niƙa zuwa matakin yanzu.

Lokacin aikawa: Juni-02-2022