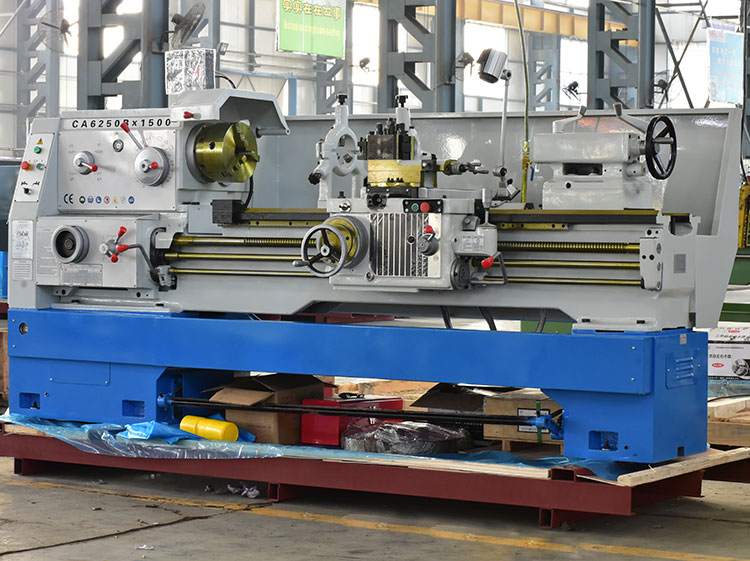

Lathes na yau da kullun sune lathes a kwance waɗanda zasu iya aiwatar da nau'ikan kayan aiki iri-iri kamar su shafts, fayafai, zobe, da sauransu. hakowa, reaming, tapping da knurling, da sauransu.

tsarin aiki

Babban abubuwan da ke cikin lathe na yau da kullun sune: kayan kwalliya, akwatin ciyarwa, akwatin faifai, hutun kayan aiki, kayan wutsiya, dunƙule santsi, dunƙule gubar da gado.

Headstock: Wanda kuma aka fi sani da headstock, babban aikinsa shi ne ya wuce motsin juyawa daga babban motar ta hanyar jerin hanyoyin canza saurin gudu ta yadda babban igiya zai iya samun saurin gudu daban-daban na gaba da baya, kuma a lokaci guda. headstock yana raba ɓangaren motsin Wucewa wutar lantarki zuwa akwatin ciyarwa.Matsakaici na Headstock shine maɓalli na ɓangaren lathe.Santsin sandar sandar da ke gudana a kan abin ɗamara kai tsaye yana rinjayar ingancin aikin aikin.Da zarar an rage daidaiton juyawa na sandal, za a rage ƙimar amfani da kayan aikin injin.

Akwatin ciyarwa: Har ila yau, an san shi da akwatin kayan aiki, akwatin ciyarwa yana sanye da tsarin canjin saurin ciyar da motsi.Daidaita tsarin canjin saurin don samun adadin abincin da ake buƙata ko farar, kuma aika motsi zuwa wuka ta hanyar dunƙule mai santsi ko dunƙule gubar.tara don yankan.

Gubar dunƙule da dunƙule santsi: ana amfani da su don haɗa akwatin ciyarwa da akwatin zamewa, da watsa motsi da ƙarfin akwatin ciyarwa zuwa akwatin zamewa, ta yadda zamewar.

live top

Akwatin yana samun motsi na madaidaiciyar madaidaiciya.Ana amfani da dunƙule gubar musamman don juya zaren daban-daban.Lokacin juya sauran saman kayan aikin, kawai dunƙule mai santsi ana amfani da shi, kuma ba a amfani da dunƙule gubar.

Akwatin zamewa: Akwatin sarrafawa ce don motsin ciyarwar lathe.An sanye shi da wata hanyar da ke juyar da motsin jujjuyawar sandar haske da dunƙule gubar zuwa motsi na linzamin kayan aikin sauran.Motsin ciyarwar a tsaye da motsin ciyarwar kayan aikin sauran ana samun su ta hanyar watsa haske.Kuma saurin motsi, ta hanyar dunƙule don fitar da mariƙin kayan aiki don yin motsi na madaidaiciya madaidaiciya, ta yadda za a juya zaren.

Mai riƙe kayan aiki: Mai riƙe kayan aiki ya ƙunshi nau'ikan masu riƙe kayan aiki da yawa.Ayyukansa shine matsa kayan aiki da sanya kayan aiki ya motsa a tsaye, a gefe ko a bayyane.

Tailstock: Shigar da cibiyar baya don saka tallafi, kuma za ta iya shigar da kayan aikin sarrafa ramuka irin su drills da reamers don sarrafa ramuka.

Bed: Ana shigar da manyan sassan lathe akan gado, don su kula da daidaitaccen matsayi na dangi yayin aiki.

kari

1. Hudu-muƙamuƙi Chuck (na cylindrical workpieces), hudu-jaw Chuck (ga saba aiki workpieces)

2. Cibiyar Live (don gyara kayan aiki)

3. Tsarin tsakiya (stable workpiece)

4. Tare da mariƙin wuƙa

babban siffa

1. Babban karfin juyi a ƙananan mitar da tsayayyen fitarwa

2. High-performance vector iko

3. Amsa mai ƙarfi mai ƙarfi da sauri da daidaiton saurin daidaitawa

4. Rage sannu da tsayawa da sauri

5. Ƙarfin ƙarfin hana tsangwama

Hanyoyin aiki

1. Dubawa kafin tuki

1.1 Ƙara man shafawa mai dacewa bisa ga ginshiƙi na mashin.

1.2 Bincika duk wuraren lantarki, rikewa, sassan watsawa, karewa da na'urori masu iyaka sun cika, abin dogaro da sassauƙa.

1.3 Kowane kaya ya kamata ya kasance a matsayi na sifili, kuma bel ɗin ya kamata ya dace da bukatun.

1.4 Ba a yarda a adana kayan ƙarfe kai tsaye a kan gado ba, don kada ya lalata gado.

1.5 Kayan aikin da za a sarrafa ba shi da laka da yashi, yana hana laka da yashi faɗuwa a cikin pallet da kuma cire layin jagora.

1.6 Kafin a danne kayan aikin, dole ne a gudanar da gwajin motar fanko.Bayan tabbatar da cewa komai na al'ada ne, ana iya loda kayan aikin.

2. Hanyoyin aiki

2.1 Bayan an shigar da kayan aikin, fara famfo mai mai mai da farko don sanya matsin mai ya dace da kayan aikin injin kafin farawa.

2.2 Lokacin daidaita ma'aunin kayan aikin musayar, lokacin daidaita dabaran rataye, dole ne a yanke wutar lantarki.Bayan daidaitawa, dole ne a ɗaure dukkan kusoshi, a cire maƙarƙashiya a cikin lokaci, kuma ya kamata a cire haɗin aikin don aikin gwaji.

2.3 Bayan lodawa da sauke kayan aikin, chuck wrench da iyo sassa na workpiece ya kamata a cire nan da nan.

2.4 Za a daidaita kayan aikin injin wutsiya, ƙugiya, da dai sauransu zuwa wurare masu dacewa bisa ga buƙatun sarrafawa, kuma za a ɗaure ko ɗaure.

2.5 Kayan aiki, kayan aiki da kayan aiki dole ne a ɗora su cikin aminci.Dole ne kayan aikin ƙarfi mai iyo dole ya shimfiɗa ɓangaren jagora zuwa cikin kayan aiki kafin fara kayan aikin injin.

2.6 Lokacin amfani da hutun cibiyar ko sauran kayan aiki, dole ne a daidaita cibiyar da kyau, kuma dole ne a sami lubrication mai kyau da wuraren tallatawa.

2.7 Lokacin sarrafa dogayen kayan aiki, ɓangaren da ke fitowa a bayan babban shaft bai kamata ya yi tsayi da yawa ba.

2.8 Lokacin ciyar da wuka, wuka ya kamata ya kusanci aikin a hankali don guje wa karo;gudun abin hawa ya zama uniform.Lokacin canza kayan aiki, kayan aiki da kayan aikin dole ne su kula da nesa mai kyau.

2.9 Dole ne a ɗaure kayan aikin yankan, kuma tsayin tsayin kayan aikin juyawa gabaɗaya baya wuce sau 2.5 na kauri na kayan aiki.

2.1.0 Lokacin da ake yin sassan eccentric, dole ne a sami madaidaicin kiba don daidaita tsakiyar nauyi, kuma saurin abin hawa ya kamata ya dace.

2.1.1.Dole ne a sami matakan kariya ga kayan aikin da suka wuce fuselage.

2.1.2 Daidaita saitin kayan aiki dole ne ya kasance a hankali.Lokacin da tip ɗin kayan aiki ya kasance 40-60 mm nesa da ɓangaren sarrafa kayan aikin, yakamata a yi amfani da jagora ko abinci mai aiki a maimakon haka, kuma ba a yarda da saurin ciyarwa kai tsaye shigar da kayan aikin ba.

2.1.3 Lokacin goge kayan aikin tare da fayil, mariƙin kayan aiki yakamata a dawo da shi zuwa wuri mai aminci, kuma mai aiki yakamata ya fuskanci chuck, tare da hannun dama a gaba da hannun hagu a baya.Akwai hanya mai maɓalli a saman, kuma ba a ba da izinin sarrafa kayan aiki tare da ramin murabba'i da fayil ba.

2.1.4 Lokacin polishing da'irar waje na workpiece tare da Emery zane, mai aiki ya kamata ya riƙe iyakar biyu na Emery zane tare da hannaye biyu don goge bisa ga matsayi da aka ƙayyade a cikin labarin da ya gabata.An haramta amfani da yatsunsu don riƙe mayafin da zai goge rami na ciki.

2.1.5 A lokacin ciyar da wuka ta atomatik, ƙaramar mariƙin wuƙa ya kamata a daidaita shi don a haɗa shi da tushe don hana tushe daga taɓa chuck.

2.1.6 Lokacin yankan manyan kayan aiki ko kayan aiki masu nauyi, isassun izinin injin ya kamata a tanadi.

3. Yin kiliya

3.1 Yanke wutar lantarki kuma cire kayan aikin.

3.2 Hannun kowane bangare suna rushewa zuwa matsayi na sifili, kuma ana ƙidaya kayan aikin da tsaftacewa.

3.3 Duba yanayin kowace na'urar kariya.

4. Kariya yayin aiki

4.1 An haramta shi sosai ga waɗanda ba ma'aikata ba suyi aiki da injin.

4.2 An haramta shi sosai don taɓa kayan aiki, ɓangaren jujjuyawar kayan aikin injin ko kayan aikin juyawa yayin aiki.

4.3 Ba a yarda a yi amfani da tasha na gaggawa ba.A cikin yanayin gaggawa, bayan amfani da wannan maɓallin don tsayawa, yakamata a sake duba shi bisa ga ƙa'idodi kafin fara kayan aikin injin.

4.4 Ba a yarda a taka saman layin dogo na jagora, sandar dunƙulewa, sanda mai goge baki, da sauransu na lathe.Sai dai ga ƙa'idodi, ba a ba da izinin yin aiki da hannu tare da ƙafafu maimakon hannu ba.

4.5 Don sassan da blisters, ramukan raguwa ko maɓalli a bangon ciki, ba a ba da izinin scrapers na triangular su yanke ramukan ciki ba.

4.6 Matsakaicin iska ko matsa lamba na ruwa na pneumatic rear hydraulic chuck dole ne ya kai ƙayyadadden ƙimar kafin a iya amfani da shi.

4.7 Lokacin da juya siriri workpieces, a lokacin da protruding tsawon gaban biyu na kan gadon ya fi 4 sau diamita, ya kamata a yi amfani da cibiyar bisa ga tsari dokokin.Taimakon hutun tsakiya ko hutun diddige.Ya kamata a ƙara masu tsaro da alamun gargaɗi lokacin da suke fitowa a bayan kan gadon.

4.8 Lokacin da ake yanke karafa ko yankan sauƙi a fantsama (ciki har da niƙa), ya kamata a ƙara baffles masu kariya, kuma masu aiki su sa gilashin kariya.

Sharuɗɗan Amfani

Amfani na yau da kullun na lathes na yau da kullun dole ne ya dace da waɗannan sharuɗɗan: canjin wutar lantarki a wurin kayan aikin injin yana da ƙanƙanta, yanayin zafin jiki yana ƙasa da digiri 30 ma'aunin Celsius, kuma ƙarancin dangi bai wuce 80%.

1. Abubuwan da ake bukata na muhalli don wurin da kayan aikin inji

Ya kamata wurin da kayan aikin injin ya kasance da nisa daga tushen girgiza, ya kamata a guji hasken rana kai tsaye da hasken zafi, kuma a guji tasirin zafi da iska.Idan akwai tushen jijjiga kusa da kayan aikin injin, yakamata a saita ramukan hana girgiza kewaye da kayan aikin injin.In ba haka ba, kai tsaye zai shafi daidaiton injina da kwanciyar hankali na kayan aikin injin, wanda zai haifar da mummunan hulɗar kayan aikin lantarki, gazawa, kuma yana shafar amincin kayan aikin injin.

2. Bukatun wutar lantarki

Gabaɗaya, ana shigar da lathes na yau da kullun a cikin aikin injina, ba kawai yanayin yanayin yanayi ya canza sosai ba, yanayin amfani ba shi da kyau, amma kuma akwai nau'ikan kayan aikin lantarki da yawa, wanda ke haifar da manyan canje-canje a cikin wutar lantarki.Don haka, wurin da ake shigar da lathes na yau da kullun yana buƙatar kulawa da ƙarfin wutar lantarki.Dole ne madaidaicin ƙarfin wutar lantarki ya kasance cikin kewayon da aka yarda kuma ya kasance da ƙarfi.In ba haka ba, aikin al'ada na tsarin CNC zai shafi.

3. Yanayin zafi

Yanayin zafin jiki na lathes na yau da kullun ya yi ƙasa da digiri 30 ma'aunin celcius, kuma yanayin zafin dangi bai wuce 80%.Gabaɗaya magana, akwai mai shaye-shaye ko fanka mai sanyaya a cikin akwatin sarrafa wutar lantarki na CNC don kiyaye zafin aiki na kayan aikin lantarki, musamman sashin sarrafawa na tsakiya, akai-akai ko bambancin zafin jiki yana canzawa kadan.Yawan zafin jiki da zafi mai yawa zai rage rayuwar sassan tsarin sarrafawa kuma ya haifar da ƙara yawan kasawa.Ƙara yawan zafin jiki da zafi, da ƙurar ƙura za su haifar da haɗin kai a kan allon da aka haɗa da kuma haifar da gajeren kewaye.

4. Yi amfani da kayan aikin inji kamar yadda aka ƙayyade a cikin littafin

Lokacin amfani da kayan aikin injin, ba a yarda mai amfani ya canza sigogi da masana'anta suka saita a cikin tsarin sarrafawa yadda ya kamata.Saitin waɗannan sigogi yana da alaƙa kai tsaye da halaye masu ƙarfi na kowane ɓangaren kayan aikin injin.Ƙimar madaidaicin ramuwa kawai za a iya daidaita su bisa ga ainihin halin da ake ciki.

Mai amfani ba zai iya canza na'urorin haɗi na kayan aikin injin yadda ya so ba, kamar yin amfani da chuck na hydraulic fiye da ƙayyadaddun bayanai.Mai ƙira yayi cikakken la'akari da daidaita ma'aunin mahaɗi daban-daban lokacin saita kayan haɗi.Sauyawa makaho yana haifar da rashin daidaituwa na sigogi a cikin hanyoyin haɗin gwiwa daban-daban, har ma yana haifar da hatsarori na bazata.Matsa lamba na chuck na hydraulic, kayan aiki na kayan aiki, kayan aiki na ruwa da kuma silinda na hydraulic ya kamata su kasance cikin kewayon damuwa da aka yarda, kuma ba a yarda ya karu ba bisa ka'ida ba.

Lokacin aikawa: Satumba-09-2022